1) Automatic Step-Lap cutting line for transformer core, and cover up to the sheet width 30-300mm.

2) Automatic Feeding, Hole Punch, Two V-Notch, Swing Shear Cutting ,Two Machine Arms receiving.

3) Fully electric running with lower noise and energy conservation.

4) Compact design better than traditional machine, less floor space for installation.

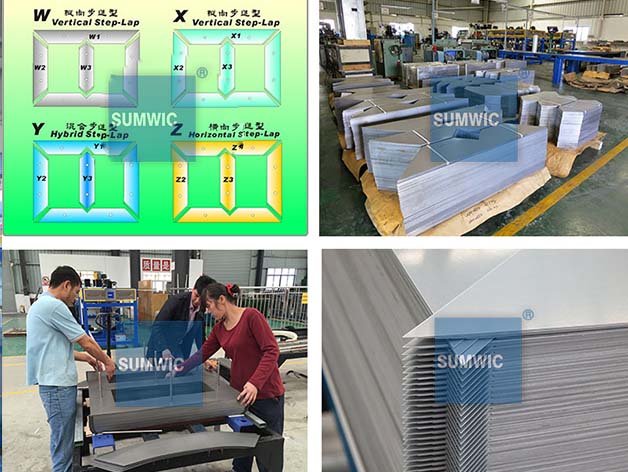

5) Process all kind of transformer laminations. Vertical Step-Lap (3/5/7 Steps), Hybrid Step-Lap (3/5/7 Steps), Horizontal Step-Lap (3/4/5/6/7 Steps).

6) Panasonic (Japan) servo motor and computer system, imported servo reducer, ball screw, linear guide and bearings.

7) High Precision with Tolerance +/- 0.10mm, cutting speed more than 70pcs/min.

SCRV-series step lap cutting line have been designed and built by SUMWIC company, we use the good quality accessories with famous brand, includes Panasonic servo system and PLC (Japan), Servo Reducer(Taiwan), ball screw and linear guideway from Germany and Taiwan, other SMC Pneumatic components and electrical components from Japan. Automatically cut side leg, York and center leg with high precision and high performance.

The decoiler is made of high quality steel, match the motor from overseas with lower noise and high efficiency. The feed speed could be controlled by the Panasonic frequency converter, which best speed match with the main unit, besides, it could forward and reverse the raw material , and the electrical sheet could be back by reverse function. The decoiler with expanded function which is suitable for the different size sheet coil, and the feeding speed up to 80m/min, the max load is about 2000KG.

Equipped with high performance Panasonic FP Series control system, which be able to generate accurate output pulse, and make the instruction cycle more faster and stable. The program is designed to integrate sophisticated function to greatly reduce the time used by operator for data input. Besides, the self protecting program for all actions performed by the machine to avoid the damage.

Using 15 inch Taiwan WEINVIEW HIM touch screen, equipped with the ARM9 400MHz CPU, and with clear and user friendly software, which boost the data processing and image display.

SCRV Series Step-lap core cutting line equipped with 12 Pcs Panasonic servo motors to realize the corresponding action. High-speed communication of 5Mbpulse/s achieves ultra-high-precision position control. It is faster and more stable than the traditional 500Kbpulse/s. It also greatly reduces the problem of interference between axis and axis. Equipped with SESAME special reducer from Taiwan, which has high efficiency, lower back lash, and lower noise. Besides, the design structure is more compact with light weight.

Ballscrews: consist of a screw spindle and a nut integrated with rolling elements that cycle through a return mechanism. Ballscrews convert rotary motion into linear motion, and are most commonly used in industrial machinery and precision machines. Hiwin precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life.

Linear guideways: provide a type of linear motion that utilizes re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guideway is only 1/50 compared to a traditional slide and are able to take loads in all directions. With these features, a linear guideway can achieve high precision and greatly enhanced moving accuracy.

Using Sumitomo servo reducer with zero backlash, which ensure the swing unit to accurately rotate with high efficiency and less vibration. The cutter be made of the tungsten carbide material with good abrasive resistance, besides, it has good resistance to elevated temperature which improved the cutting speed.

The hole-punch unit add the move function,which is easier to adjust the center position of raw material. Besides, the eccentric hole punch function is added which could adjust the distance freely, and thus increased the diversity of lamination sheet and enriched the production line, furthermore, it makes the replacement of moulds more convenient and faster.

The step lap core cutting machine use the unique design of dual V- notch unit and rotary shear unit, which could greatly shorten the length of the production line, and realize the multi-functional high speed cutting, meanwhile, it can notch different shape of silicon sheet, so that meets the design requirements of different transformer.

Model | SCRV-300 | SCRV-420 |

Material Width | 30~300 mm | 40~420 mm |

Material Thickness | 0.18 ~ 0.50 mm | 0.18 ~ 0.50 mm |

Hole Size | Ø 6 ~ Ø 25mm | Ø 6 ~ Ø 25mm |

Speed | 0-120m/min | 0-120m/min |

Accuracy | ±0.1 mm (<1000mm) | ±0.1 mm (<1000mm) |

Burrs | ≤0.02mm | ≤0.02mm |

Panasonic Servo Motor | 12 Sets | 12 Sets |

Hole Punch | 1 | 1 |

V-Notch | 2 | 2 |

Swing Shear | 1 | 1 |

Magnetic Arm | 2 | 2 |

Voltage | 380VAC, 50/60Hz or Optional | 380VAC, 50/60Hz or Optional |

Capacity | 22 KW | 26KW |

Power Consumption | 1.5KWH | 2KWH |

Language | Chinese/English | Chinese/English |

Size (LxWxH) | Main Unit: 2400 x 1250 x1700 mm | Main Unit: 3500 x 1500 x1700 mm |

Stacker: 2600 x 1300 x1400 mm | Stacker: 3200 x 1600 x1400 mm | |

Decoiler: 1640x 900 x 1400 mm | Decoiler:1640x 1400 x 1600 mm | |

Weight | Main Unit: 3200 kg | Main Unit:4250 kg |

Stacker: 1250kg | Stacker: 1500kg | |

Decoiler: 1200kg | Decoiler: 1200kg | |

Floor Space | 8.5x2m | 10x2m |

Model | SCRV-300 |

Type | Single head |

Expansion | Powered |

Max. Coils OD | 1200mm |

Expand Range ID | 450-508mm (Standard) |

Max. Coils Loading | 2000kg |

Max. Feeding Speed | 80m/min |

Size (LxWxH) | 1640x900x1400mm |

Weight | 1200KG |

Copyright © 2024 SUMWIC MACHINERY CO., LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.