How much will it take for core cutting machine materials?

2020-08-06

While in the business of producing core cutting machine, the material cost can be one of the biggest expenses, directly affecting profitability. But it is possible to reduce material costs without compromising end product quality and changing customer expectations and dependencies. Like most effective commercial cost reduction measures, reducing commodity costs begins with a comprehensive analysis of the various direct and auxiliary ways in which cash flows from the underlying materials are consumed. Here lists some of the ways SUMWIC MACHINERY CO., LTD does to reduce materials cost, to bring benefits to both customers and ourselves: use the lower-cost alternatives if possible, reduce waste, eliminate unnecessary product features, etc.

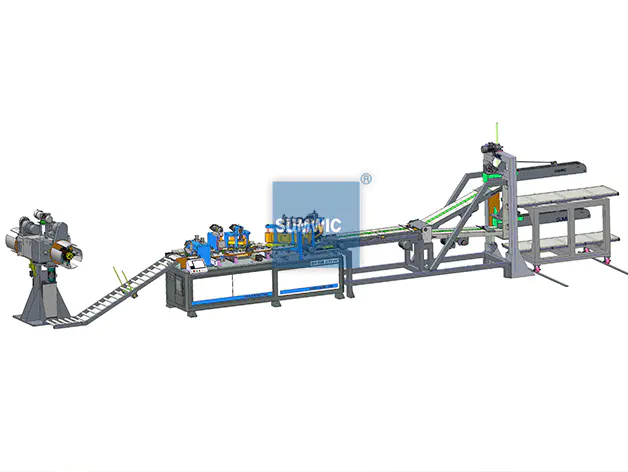

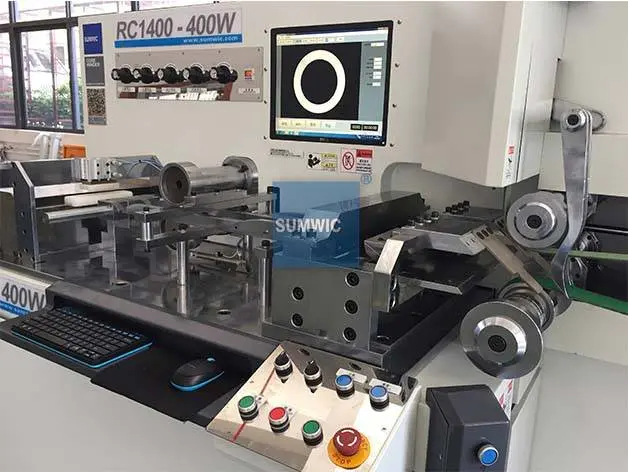

SUMWIC MACHINERY COMPANY has grown to be a Chinese top manufacturer for cut to length line. SUMWIC MACHINERY COMPANY provides a wide range of transformer winding machine for customers. SUMWIC Machinery cut to length line is produced under the vigilance of proficient professionals. SUMWIC machines sell good in US, UK, Canada,Korea, Poland, Taiwan, Singapore, India, etc. Customers who have used the product for many years praise that it has basically no pilling or plush balls. SUMWIC winding machine is driven by the constant current circuit.

We will work hard to move toward a more sustainable manufacturing model. We will try to optimize the materials usage rate so as to reduce resource waste.

SUMWIC MACHINERY COMPANY has grown to be a Chinese top manufacturer for cut to length line. SUMWIC MACHINERY COMPANY provides a wide range of transformer winding machine for customers. SUMWIC Machinery cut to length line is produced under the vigilance of proficient professionals. SUMWIC machines sell good in US, UK, Canada,Korea, Poland, Taiwan, Singapore, India, etc. Customers who have used the product for many years praise that it has basically no pilling or plush balls. SUMWIC winding machine is driven by the constant current circuit.

We will work hard to move toward a more sustainable manufacturing model. We will try to optimize the materials usage rate so as to reduce resource waste.

Custom message