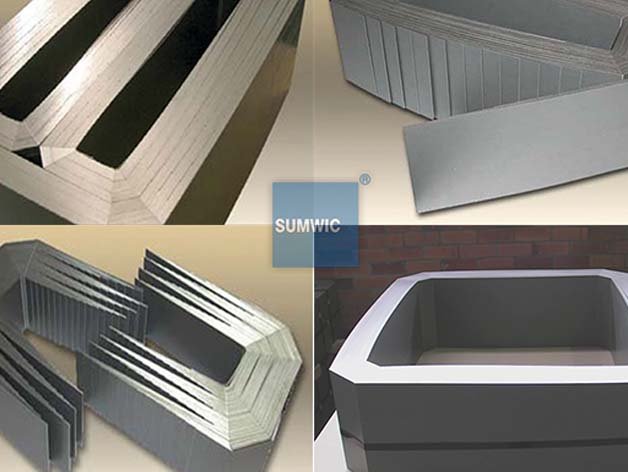

1) Produce DG core, DUO core, Un-cut core, Butt core, Step butt core, Triangle core.

2) More core options and styles allow you to satisfy your customers needs.

3) Produce an unlimited range of sizes. Core dimensions are entered into our software.

4) No more mandrels to make, store, find, fit or get wrong.

5) Smaller, lighter, reduced production floor space.

6) Lower core loss compared to C Cores, E&I and Strip Laminations.

7) Wound Core Folding Machine for transformer core, and cover up to the sheet width 20-200mm, thickness 0.18-0.50mm, length accuracy ± 0.1mm.

SCF-200 Wound Core Folding Machine mainly use in producing rectangular core, such as Butt core, DDG core, DUO core, Un-cut core and Gapped core, it equipped with the latest computer system and servo driver to control the feeding unit, folding unit and cutting unit, and it can process the strip up to 200mm.

For Distribution Transformers, Unicore Technology provides a highly flexible, accurate and reliable production system with all the inherent advantages of wound core technology, such as very low core loss, fast assembly and high output relative to capital investment.

Equipped with industrial computer control system instead of the traditional PLC system, which is more powerful, and the arithmetic speed is more faster. The function could be added greatly because of the enormous memory, besides, the software can be updated faster and convenient. This level of industrial computer can withstand bad environment such as high/low temperature or vibration.

Open the computer, user could choose the core type or angle type according to the requirements, then input the size, the computer could calculate the size of core, the class number, sheet number and the space.

In order to make the production convenient, the computer could store 20 groups core size, and user could get it from the computer easily.

SCF-200 Wound Core Folding Machine equipped with four sets Panasonic servo motors to realize the following actions:

First servo motor: it is for the feeding roller unit, which connect to the reducer and roller, to accurately feed the materials to different position for processing.

Second servo motor: it is for folding, which supply the power for fold cutter, and could adjust the folding angle by change the mechanical travel.

Third servo motor: it is for the cutting, which connect to precision reducer, then drive the tungsten carbide cutter to cut materials.

Ballscrews: consist of a screw spindle and a nut integrated with rolling elements that cycle through a return mechanism. Ballscrews convert rotary motion into linear motion, and are most commonly used in industrial machinery and precision machines.

Hiwin precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life.

Linear guideways: provide a type of linear motion that utilizes re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guideway is only 1/50 compared to a traditional slide and are able to take loads in all directions. With these features, a linear guideway can achieve high precision and greatly enhanced moving accuracy.

Model | SCF-200 | SCF-400 |

Material Width | 20~200 mm | 20~400 mm |

Material Thickness | 0.18 ~ 0.50 mm | 0.18 ~ 0.50 mm |

Speed | 0-120m/min | 0-120m/min |

Accuracy | ±0.1 mm | ±0.1 mm |

Panasonic Servo Motor | 3 | 3 |

Corner Angle | 30°, 45°, 60° | 30°, 45°, 60° |

Initial CNR(Min) | 3mm | 3mm |

Window Length(Min) | 60mm | 60mm |

Window Width(Min) | 30mm | 30mm |

Industrial Computer | 1 | 1 |

Voltage | 380VAC, 50/60Hz or Optional | 380VAC, 50/60Hz or Optional |

Capacity | 4 KW | 6KW |

Power Consumption | 1.0KWH | 1.5KWH |

Language | Chinese/English | Chinese/English |

Machine Size (LxWxH) | 1100 x 1200 x1800 mm | 1200 x 1350 x1850 mm |

Package Size (LxWxH) | 1400 x 1500 x2100 mm | 1500 x 1650 x2200 mm |

Weight | 1050 kg | 1250KG |

Model | SCF-200 |

Max. Material OD | 1200mm |

Expand Range ID | 450-508mm(Standard) |

Max. Loading | 2000kg |

Max. Feeding Speed | 80m/min |

Machine Size (LxWxH) | 1700x800x1350mm |

Package Size (LxWxH) | 2000x1100x1750mm |

Weight | 950KG |

Copyright © 2024 SUMWIC MACHINERY CO., LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.