1) Automatic 90 degree cutting line for transformer core, and can cover up to the max sheet width of 200mm, the hole size: φ8-20mm.

2) Automatic feeding, punching and cutting with high efficiency and high accuracy.

3) Use tungsten carbide steel cutter with high reliability, the accuracy is ±0. 02mm, and the max cutting speed more than 240 pcs/min.

4) Unique design, compact structure, easy operation and maintenance. Equipped with PLC, HMI touch screen, 3 sets servo motor and imported parts.

SC-series 90 degree cutting line have been designed and built by SUMWIC company, equipped with tungsten carbide steel tools to cut the Non-oriented silicon steel or Oriented silicon steel, and silicon sheet can cover 25-200mm,the accuracy is +/- 0.02mm. The lamination sheet use for electric reactor, inverter and UPS.

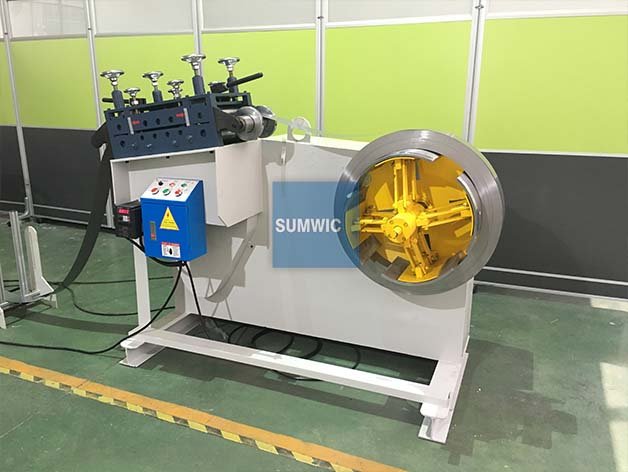

The decoiler is made of high quality steel, match the motor from overseas with lower noise and high efficiency. The feed speed could be controlled by the Panasonic frequency converter, which best speed match with the main unit, besides, it could forward and reverse the raw material, and the electrical sheet could be back by reverse function. The decoiler with expanded function which is suitable for the different diameter of coil. The decoiler equipped with the leveling unit that make sure the flatness of silicon sheet.

Equipped with high performance Delta DVP-E Series control system, which be able to generate accurate output pulse, and make the instruction cycle more faster and stable. The program is designed to integrate sophisticated function to greatly reduce the time used by operator for data input. Besides, the self protecting program for all actions performed by the machine to avoid the damage.

Using 7 inch HMI touch screen, equipped with the ARM9 400MHz CPU, and with clear and user friendly software, which boost the data processing and image display.

SC-series 90° Strip Cutting Line equipped with three sets servo motors to realize the following actions:

First servo motor: it is for the feeding roller unit, which connect to the reducer and roller, to accurately feed the materials to different position for processing.

Second servo motor: it is for hole punching, which supply the power for punch unit, then the silicon sheet will be punched hole, the hole could be change by change the punching unit.

Third servo motor: it is for the cutting, which connect to precision reducer, then drive the tungsten carbide cutter to cut silicon sheet.

Model | SC-200 | SC-300 |

Material Width | 25~200 mm | 25~300 mm |

Material Thickness | 0.10 ~ 0.50 mm | 0.10 ~ 0.50 mm |

Hole Size | Ø 8 ~ Ø 20mm | Ø 8 ~ Ø 25mm |

Cutting Length | 20-9999mm | 20-9999mm |

Accuracy | ±0.1 mm (<1000mm) | ±0.1 mm (<1000mm) |

Burrs | ≤0.02mm | ≤0.02mm |

Servo Motor | 3 Sets | 3 Sets |

Hole Punch | 1 | 1 |

Swing Shear | 1 | 1 |

Electronic Scale | 0-200KG | 0-200KG |

Voltage | 380VAC, 50/60Hz or Optional | 380VAC, 50/60Hz or Optional |

Capacity | 3 KW | 4 KW |

Language | Chinese/English | Chinese/English |

Size (LxWxH) | Main Unit: 1500 x 1050 x1300 mm | Main Unit: 1600 x 1100 x1400 mm |

Working Table: 1200 x 800 x860 mm | Stacker: 1200 x 800 x860 mm | |

Decoiler: 1700x 900 x 1400 mm | Decoiler:1700x 900 x 1400 mm | |

Weight | Main Unit: 950 kg | Main Unit:1050 kg |

Working Tabler: 200 kg | Stacker: 250 kg | |

Decoiler: 750kg | Decoiler: 800 kg | |

Floor Space | 6.0x1.0m | 7x1.2m |

Model | SC-200 |

Type | Single head |

Max. Coils OD | 1000mm |

Expand Range ID | 450-508mm (Standard) |

Max. Coils Loading | 800kg |

Max. Feeding Speed | 30m/min |

Size (LxWxH) | 1700x900x1400mm |

Weight | 750KG |

Copyright © 2024 SUMWIC MACHINERY CO., LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.