1) Automatic feeding, guiding, wrapping, winding and cutting.

2) Germany Siemens control system and HMI with high arithmetic speed and powerful functions.

3) Produce both distributed gap core and toroidal core.

4) With vertical 2-9 steps, 1-3 pieces per step.

5) The gas size and feed speed can be adjustable on the HMI.

6) The less labour and less errors by auto wrapping technology.

7) Equipped with tungsten steel cutting units to improve the durability.

8) SMC (Japan) pneumatic components, other electrical components from Europe and Japan.

9) Germany Siemens servo motor , imported servo reducer, linear guideway and bearings.

10) Winding core: OD(Max)=Ø800mm , Height=40-250mm.

The RCW800-250 Wound Core Winding Machine is designed and built for the production of toroidal core, toroidal wound core with gap or step-lap, it equipped with the latest computer system and servo drive to control the feed, the cut and winding mechanisms, and it can process the strip up to 250 mm, Max core OD up to 800mm.

For Distribution Transformers provides a highly flexible, accurate and reliable production system with all the inherent advantages of wound core technology, such as very low core loss, fast assembly and high output relative to capital investment.

Equipped with high performance Germany Siemens control system, which be able to generate accurate output pulse, and make the instruction cycle more faster and stable. The program is designed to integrate sophisticated function to greatly reduce the time used by operator for data input. Besides, the self protecting program for all actions performed by the machine to avoid the damage.

Using 12 inch Germany Siemens HIM touch screen, and with clear and user friendly software, which boost the data processing and image display.

RCW-series Wound Core Winding Machine equipped with three sets Siemens servo motors to realize the following actions:

First servo motor: it is for the feeding roller unit, which connect to the reducer and roller, to accurately feed the materials to different position for processing.

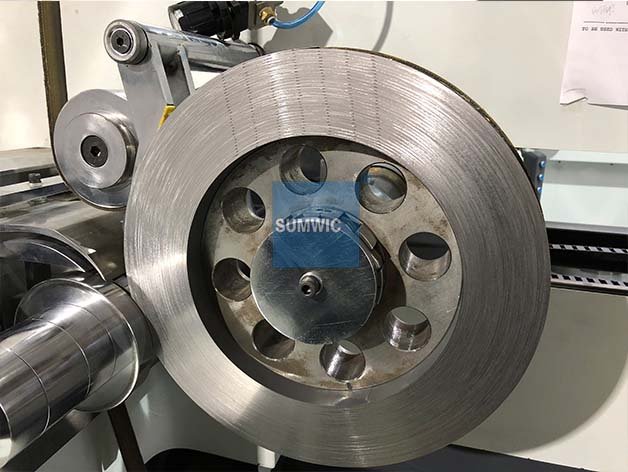

Second servo motor: it is for the cutting, which connect to precision

reducer, then drive the tungsten carbide cutter to cut materials.

Third servo motor: it is for winding, the belt drive the main shaft, the torque is strong and the positional accuracy is high

Linear guideways: provide a type of linear motion that utilizes re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guideway is only 1/50 compared to a traditional slide and are able to take loads in all directions. With these features, a linear guideway can achieve high precision and greatly enhanced moving accuracy.

The cutting tools is made of the tungsten carbide material with good abrasive resistance, besides, it has good resistance to elevated temperature which improved the cutting speed. The tungsten carbide cutter edge is more sharpper then other cutter, so the sheet is more orderly.

Model | RCW800-250 | RCW1400-400 |

Material Width | 40~250 mm | 100~400 mm |

Mandrel Diameter | Φ120-750 mm | Φ150-1350 mm |

Max. Core OD | Φ800 mm | Φ1400 mm |

Material Thickness | 0.18 ~ 0.50 mm | 0.18 ~ 0.50 mm |

Speed | 0-80m/min | 0-80m/min |

Accuracy | <0.5mm | <0.5mm |

Servo Motor | 3 | 3 |

Decoiler | 1 | 1 |

Voltage | 380VAC, 50/60Hz or Optional | 380VAC, 50/60Hz or Optional |

Capacity | 10 KW | 15KW |

Power Consumption | 2 KWH | 3 KWH |

Language | Chinese/English | Chinese/English |

Size (LxWxH) | 2500 x 1200 x1700 mm | 3600 x 1400 x1800 mm |

Weight | 1950 kg | 2580 kg |

Model | RCW800-250 |

Max. Material OD | 1200mm |

Expand Range ID | 450-508mm(Standard) |

Max. Loading | 1000kg |

Max. Feeding Speed | 80m/min |

Machine Size (LxWxH) | 1700x800x1350mm |

Package Size (LxWxH) | 2000x1100x1750mm |

Weight | 950KG |

Copyright © 2024 SUMWIC MACHINERY CO., LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.